Products & Technologies

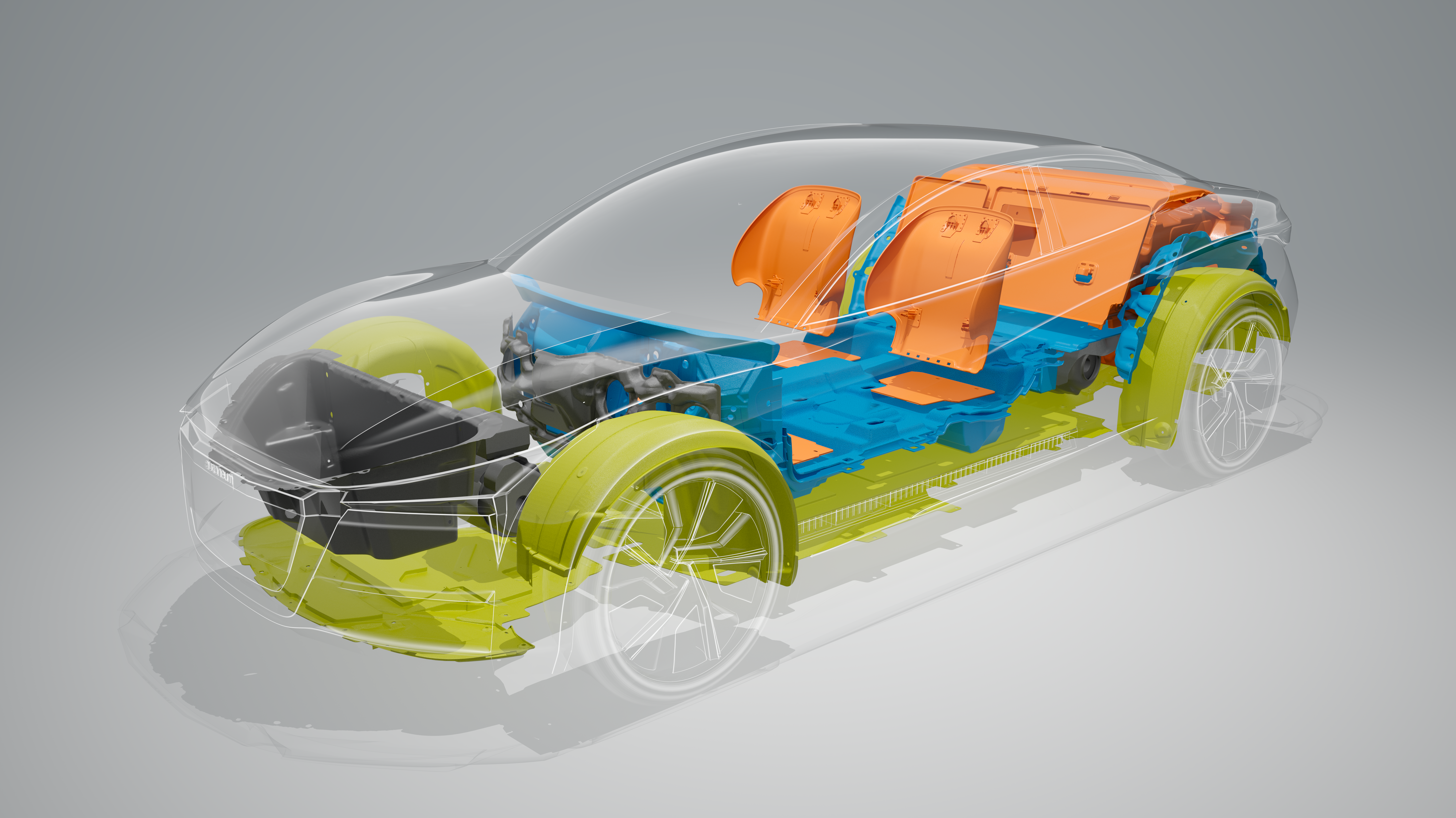

Innovative, lightweight and sustainable

Autoneum develops and produces multifunctional, lightweight and sustainable components for optimum noise and heat protection in light and commercial vehicles. The company’s product portfolio comprises systems and components for the exterior and interior of vehicles: for the engine bay, the underbody as well as for the interior floor and interior trim. These can be tailored to individual customer requirements and help to make vehicles quieter, lighter and more economical. With its global presence, Autoneum ensures the supply of automobile manufacturers operating in all key markets around the world.

The products of Autoneum reduce the interior and exterior noise of vehicles, thereby making a decisive contribution to increasing driving comfort. At the same time, the company’s technologies ensure that heat from the engine bay does not enter the passenger compartment and sensitive vehicle components are protected against extreme temperatures.

Autoneum components are lightweight, thereby reducing vehicle weight. This results in lower fuel and energy consumption and correspondingly reduced CO2 emissions and a greater driving range for electric vehicles. In this way, both man and the environment benefit from the innovative developments of the market leader in acoustic and thermal management.

The protection of natural resources is the focus of Autoneum’s production processes. The company therefore pursues the efficient use of raw materials and strives for the greatest possible recyclability of its manufactured components and systems and the reprocessing of production waste.