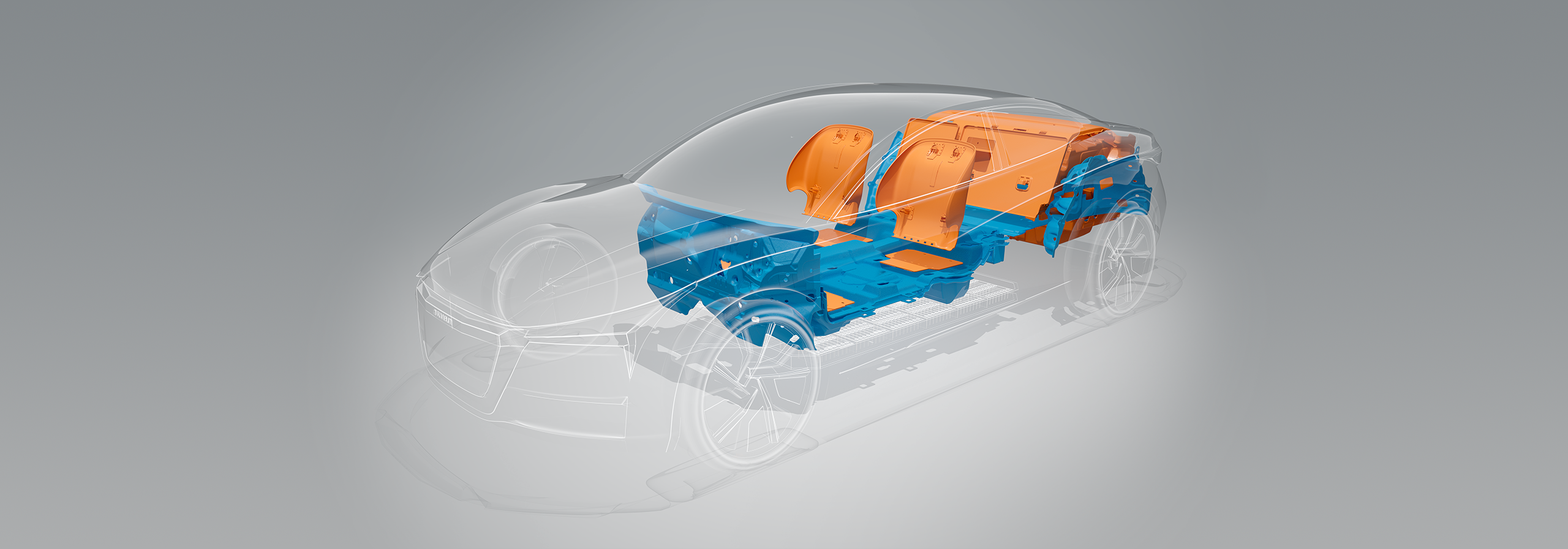

Interior components for light vehicles

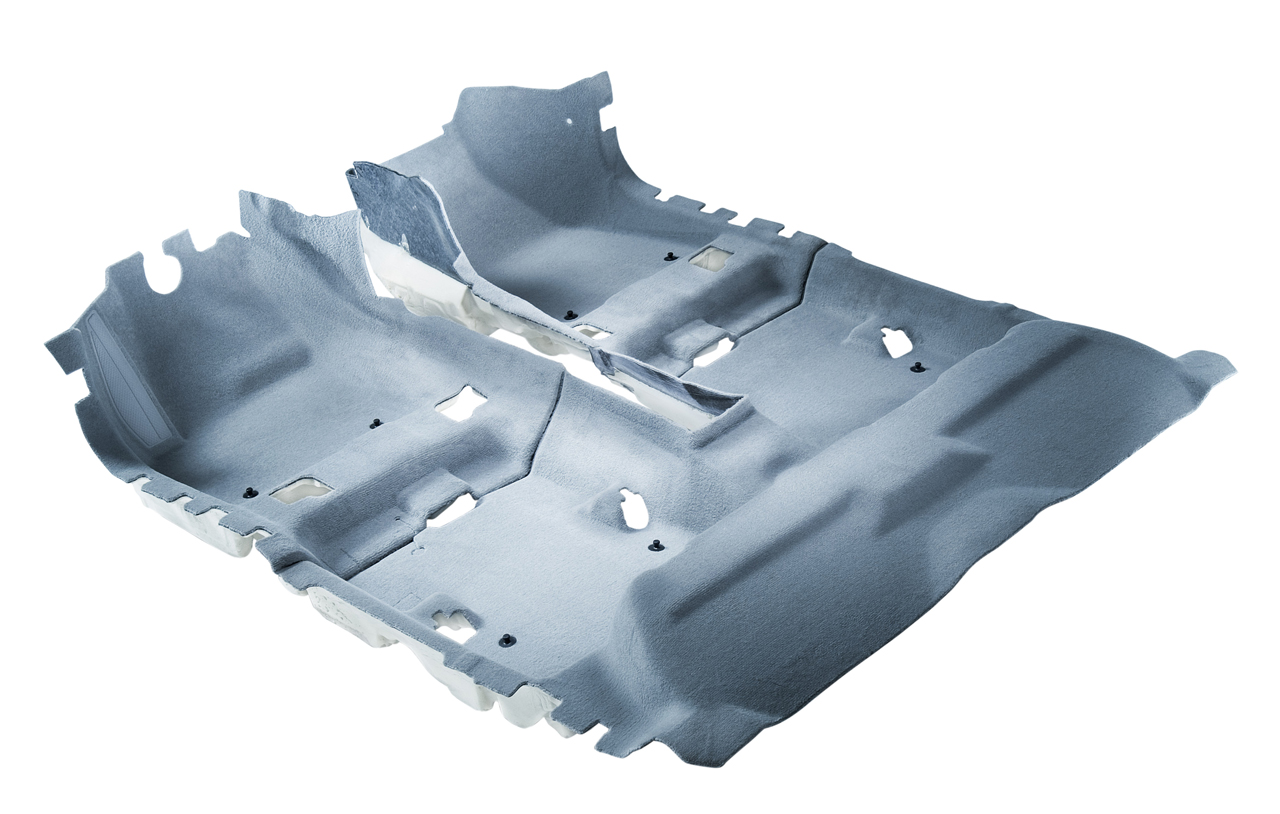

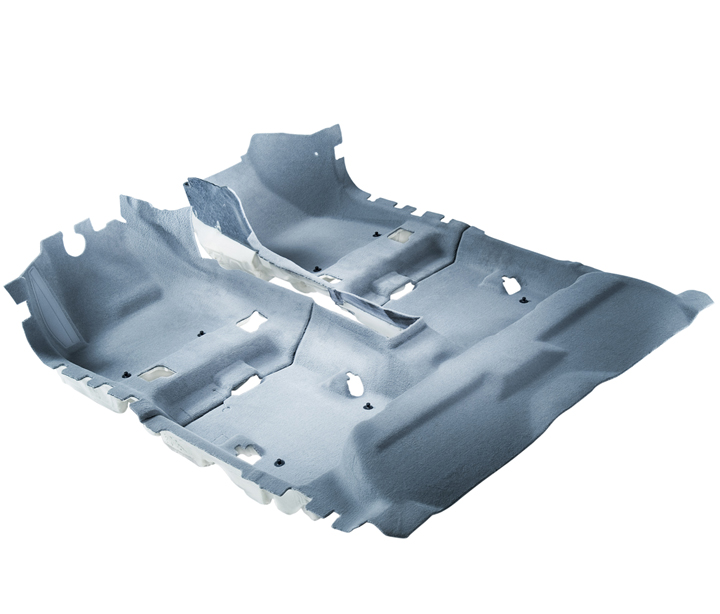

Interior floor

Autoneum’s interior floor products make vehicles lighter, more comfortable and environmentally friendly while providing optimum acoustic performance. In addition, these multifunctional components also meet the increased requirements for comfortable vehicle interiors thanks to their outstanding cleanability, low odor and high durability.

Autoneum offers the following products among others for application on the interior floor:

Interior trim

In view of the advancing electrification of mobility, noise reduction in the trunk area of vehicles is becoming increasingly important. Thanks to their high proportion of recycled material, Autoneum’s interior trim components are particularly sustainable. In addition, these multifunctional components are lightweight, extremely durable and have an aesthetically pleasing appearance.

Autoneum offers the following products among others for interior trim application:

Technologies for the vehicle interior

Technologies for the interior floor

Relive-1

Particularly sustainable

With Relive-1, Autoneum offers a premium technology for automotive carpets that not only scores with its aesthetic appearance, but also has an exceptional environmental performance.

Among other things, carpets made of Relive-1 feature a particularly sustainable use of raw materials: For example, only recycled PET bottles are used to manufacture the carpet yarns. Autoneum reuses this raw material, thus conserving natural resources and reducing plastic waste – while at the same time ensuring that new, high-quality carpet systems for future vehicle generations can be produced cost-effectively from used PET bottles. Moreover, Relive-1 is an important step towards mono-material constructions and consequently, zero waste tufted carpet production.

At the same time, Relive-1 stands for the above-average product quality of Autoneum: Compared to standard carpets in compact and to large class vehicles, Relive-1 carpets are more robust thanks to significantly higher abrasion resistance, and easy to clean thanks to the vertical alignment of the filaments and the water repellency of polyester. As a result, small particles such as wood splinters, dust or pebbles as well as liquids can be removed easily with no residual traces, which is a key benefit for recreational vehicles like SUVs. For premium class vehicles, the marriage of outstanding performance and sustainability defines nowadays the new luxury.

Di-Light

Enhanced Driving Comfort

The Di-Light carpet innovation for compact and medium class vehicles is the most recent expansion of the company’s product portfolio. Thanks to its greater abrasion resistance and resilience, Di-Light is a more durable non-woven carpet and offers an attractive appearance even in highly curved carpet areas due to its uniform surface finish.

The non-woven carpet absorbs noise entering the passenger compartment from the road or engine bay, thereby contributing to enhanced driving comfort. In addition, Di-Light has a lighter weight than standard non-woven carpets while maintaining their benefits. Di-Light-based carpets therefore reduce fuel consumption and emissions at the same time.

The enhanced resistance/weight ratio and the homogeneous look and feel of the carpet are based on newly developed fibers. Depending on the product variant, they consist of up to 97% of recycled PET which is reflected in the carpet’s excellent environmental performance.

Clean-Tuft

Premium Carpet Quality

This new technology for tufted carpets has a number of advantages compared to the non-woven carpets mainly used in the compact and medium class. Thus, also drivers of these vehicle classes benefit from the quality standard and the look and feel of premium carpeting.

Most notable is the fact that Clean-Tuft offers a clearly improved cleanability compared to non-woven floor coverings: In particular, small particles such as splinters or needles can be removed more easily and thoroughly because they do not adhere to the fabric.

Carpet systems based on Clean-Tuft are also a convincing proposition in terms of durability and abrasion resistance, being more robust than non-woven carpets and less susceptible to wear and tear. It is common for non-woven carpets to gradually lose their pile after several years in a vehicle. On the contrary, Clean-Tuft continues to offer high-quality haptic and an attractive appearance thanks to its virtually unchanged fiber shape and structure for the entire life of the vehicle.

Furthermore, Clean-Tuft rights itself much more rapidly after being subjected to strain, for example by passengers’ shoes, than conventional non-woven floor coverings and offers high stain-resistance thanks to its hydrophobic surface.

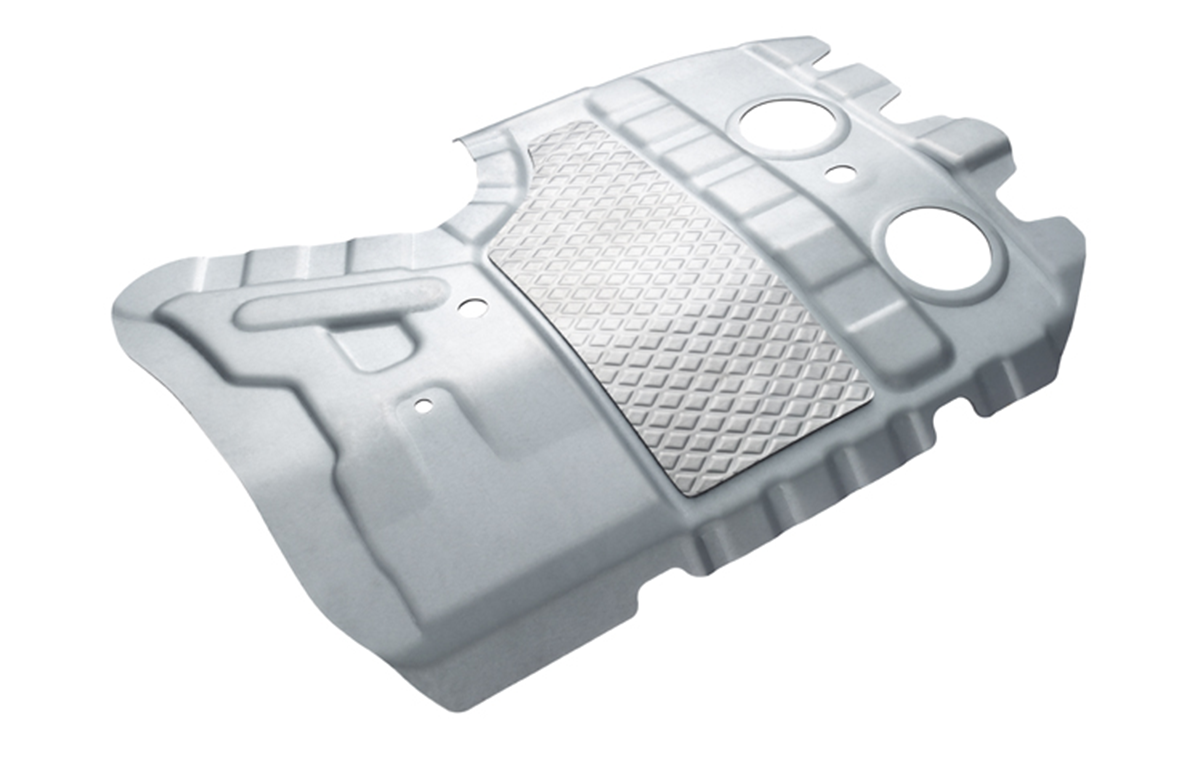

Hybrid-Acoustics

Combination of Insulation and Absorption

Inner dashes and floor insulators prevent the transfer of street noise into the passenger compartment. With Hybrid-Acoustics, Autoneum offers an innovative technology for such components that simultaneously insulates and absorbs noise.

Hybrid-Acoustics not only meets today’s but also future noise protection requirements of vehicle manufacturers. For example, the lower part of an inner dash needs more insulation as the noise of the engine and front wheels is particularly audible here. By contrast, the upper part of inner dashes requires more absorption as other parts of the car – such as the dashboard – already contribute towards insulation.

Hybrid-Acoustics enables the thickness and density – and hence the insulation and absorption capacity – of the components to be defined accurately within a centimeter without any additional materials or layers. It is done simply through the targeted engineering of the fibrous top layer. This can be achieved by means of 3D calculations and statistical energy analyses as well as modern production processes.

Components based on Hybrid-Acoustics largely consist of recycled cotton fibers and are correspondingly light. They are up to 50 percent lighter than conventional insulations made of heavy layer foam. The Hybrid-Acoustics technology accordingly makes an important contribution towards reducing vehicle weight and emissions.

Prime-Light

Quantum Leap for Inner Dashes and Floor Insulators

Prime-Light is the latest advancement of Autoneum’s successful Ultra-Light technology and represents a quantum leap in terms of innovation within the segment of inner dashes and floor insulators for vehicles. Prime-Light components can be pressed into a wide variety of different shapes and sizes. This way they adjust optimally to the individual body-in-white shapes and take account of increasingly complex production processes in vehicle construction.

Prime-Light also convinces with a light weight while maintaining the same level of acoustic protection. Thanks to a 30 percent weight reduction compared with previous models, Prime-Light-based inner dashes and floor insulators save more than two kilos of a vehicle’s weight in average.

Automobile manufacturers and end consumers equally benefit from this weight reduction: If, for instance, the weight of a vehicle is reduced by 100 kilograms by means of lightweight materials, this leads to a 0.55-liter reduction of gasoline and almost 13 grams less CO₂ emissions per 100 kilometers driven (based on total fuel consumption of 5.5 liters per 100 kilometers).

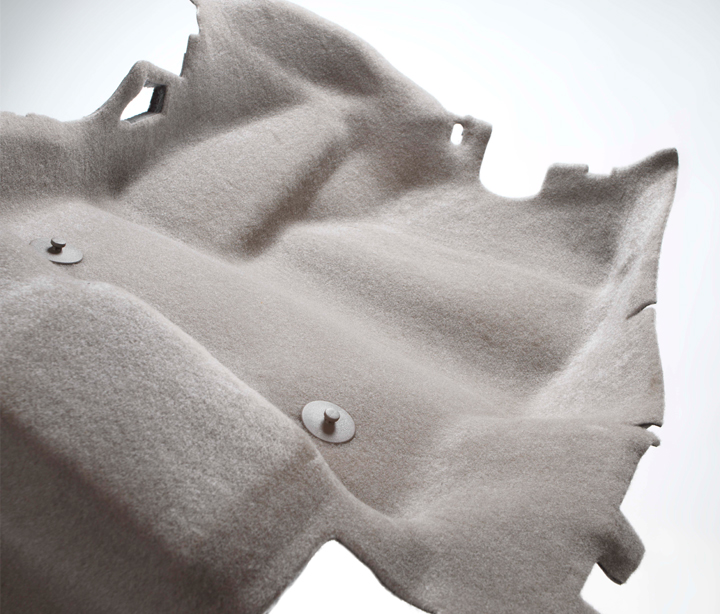

Prime-Light-based inner dashes and floor insulators consist of thermoplastic cotton felt compounds in which the share of recycled materials amounts to up to 50 percent depending on the application-specific composition. In order to achieve the greatest possible acoustic protection, Autoneum analyzes the ideal density and thickness of these components already in the design phase of new vehicle models.

Ultra-Light

The Lightweight “Classic”

The Ultra-Light technology facilitates enhanced acoustic comfort in cars while simultaneously reducing the vehicle weight and is today one of the classic products in Autoneum’s noise protection portfolio.

Prior to the market launch of Ultra-Light in 1998, vehicle manufacturers largely used insulations made of heavy layer foam to curb unwanted noise. Autoneum introduced a pioneering paradigm shift in its approach to reducing vehicle noise by focusing on the absorption of noise instead of the insulation method that had previously been practiced. While sound-insulating components block noise and prevent it from seeping through from the engine bay to the passenger compartment, sound-absorbing components “swallow” noise.

The benefits of this fundamental paradigm shift are obvious: products for the absorption of noise like inner dashes and floor insulators are made of lightweight materials such as fibers. Compared with heavier mineral oil-based insulations they enable weight savings of up to 50 percent to be made. Moreover, products based on Ultra-Light are easy to recycle.

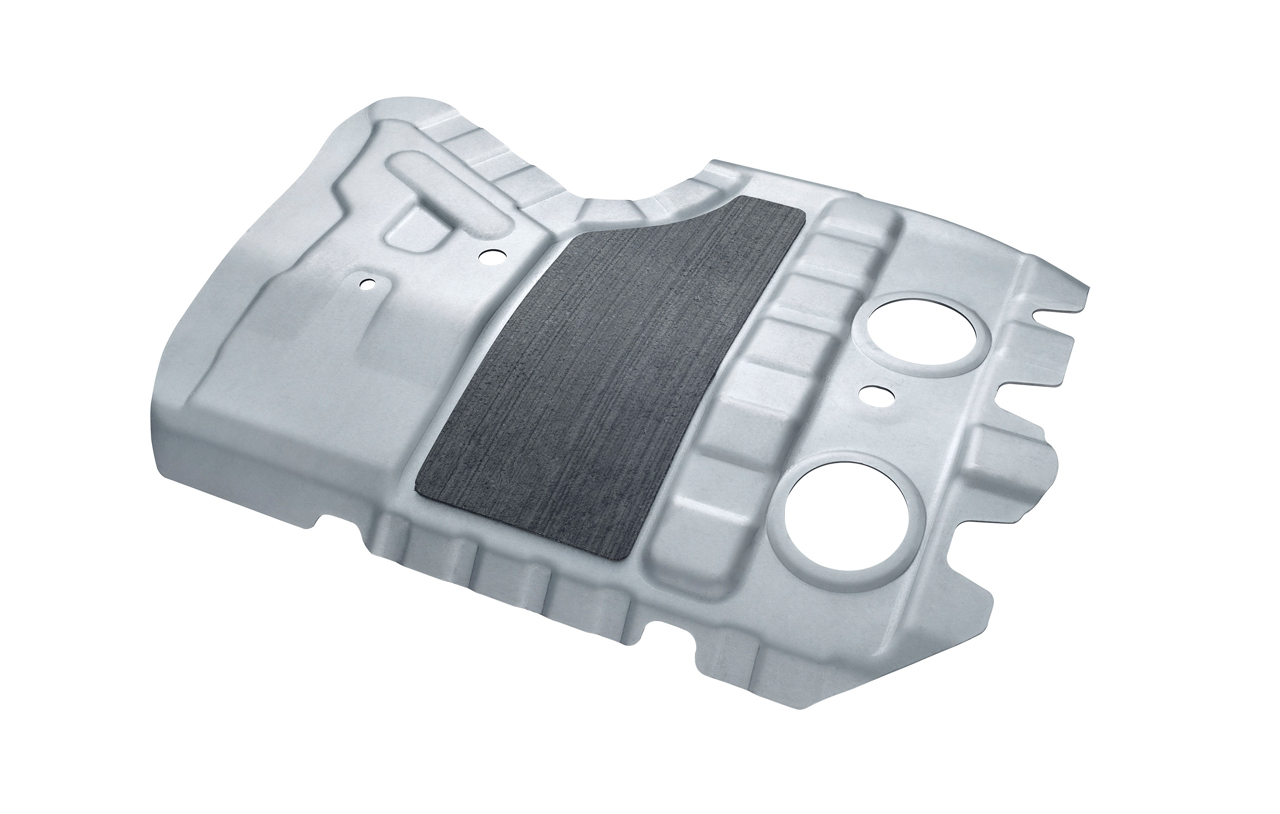

IFP-R2

Sets sustainable standards for felt technologies

The fully-automated IFP-R2 production systems are based on the Rotating Injection Fiber process which is an innovative, patented manufacturing process from Autoneum used for manufacturing tailor-made felt blanks for inner dashes and floor insulators in vehicles. These blanks with locally adjusted area weight are then molded into the shape required for the final product. The advanced process leads to better acoustics, lower weight and the possibility to locally increase the compressional stiffness of carpet systems for improved quality perception. Autoneum also achieves a higher environmental performance of the production process, as up to 80% of recycled fibers are possible. Reusing this material contributes to a better carbon footprint and thus to the conservation of natural resources.

AUTYL

Lightweight, Innovative Damping Solution

AUTYL provides an optimal combination of high damping capacity and light weight and is suitable for use on the body shell and after painting, among other uses. Automotive manufacturers are thus given flexibility in choosing when the product is assembled in the vehicle production process.

Thanks to excellent adhesive properties, the damping solution can be applied to flat and shaped, but also vertical or horizontal body parts, such as the front wall, the body-in-white or the wheel wells.

Compared with conventional solutions and sprayable products, AUTYL’s multi-layer composition and light weight enables to achieve better acoustic power and to exceed today’s environmental expectations and standards.

Nero-Acoustics

Acoustic Benefit at Low Weight

Nero-Acoustics achieves better acoustic performance compared with conventional solutions. Thanks to its visco-elastic properties it fits perfectly onto the bodywork. This multi-layer product is to be mounted on the vehicle in the paint shop. The self-adhesive variant can be applied to the vehicle in the final assembly stage.

Nero-Acoustics is also up to 50 percent lighter than conventional damping materials. Nero-Acoustics is also easier recyclable due to laminar particles in place of hollow microspheres.