热量管理

汽车隔热定制级工程工具和产品

从提高驾驶员舒适性到降低排放以及燃油和能源消耗,到扩大行驶里程,为了这些远大的目标,欧拓的热量管理专家正在开发适用于内燃机和电动汽车需求的工程解决方案和定制产品。

用于热量管理的轻量化汽车零部件不仅起到热量保护功效,确保电池系统尽可能维持最佳的温度条件,增加电池续航时间,同时也提高了电动汽车的整体行驶范围。此外,对车辆温度的全面管理也对乘客舱的热舒适性产生了积极影响。

在欧拓全球的热量管理实验设施中,专业知识和商业仿真软件与内部开发的独特工程工具和创新组件相结合,以满足客户的特定需求。

欧拓为其客户提供一系列的热量管理系统:

通过优化电池冷却板和电池罩下隔热系统,提高能源效率和电池性能

乘客舱的热舒适性主要得益于被动的热量解决方案,如内饰面板和地毯,以及主动的解决方案如可加热面等

隔热板、发动机舱盖及车身系统的热保护

发动机舱内的热存储方案,如装载在发动机舱或车身侧的发动机封装

网络

通过全球发展创新

我们的噪声控制专家研发、设计、测试及生产车辆零部件,并将所有零部件组装到针对每部车辆量身定制的多功能系统和组件中。欧拓在测量技术方面具备深厚的背景和实力。我们生产多样化的工具,可以满足各类材料与工艺的具体实验特征要求。

在热量管理方面,我们针对热保护区域研发各类产品和解决方案,并为实现热舒适度而研发各类实验和数值模拟方法。我们应用自身丰富的专业知识和经验,从而通过以下方式优化车辆的热量管理:

– 测量与计算

– 开发实验方法、数值模拟方法和测量系统

– 量身定制解决方案和产品

– 工作台架和真实行驶状态下的数值模拟

模拟

优化车辆振动噪声(NVH)特性的创新型软件

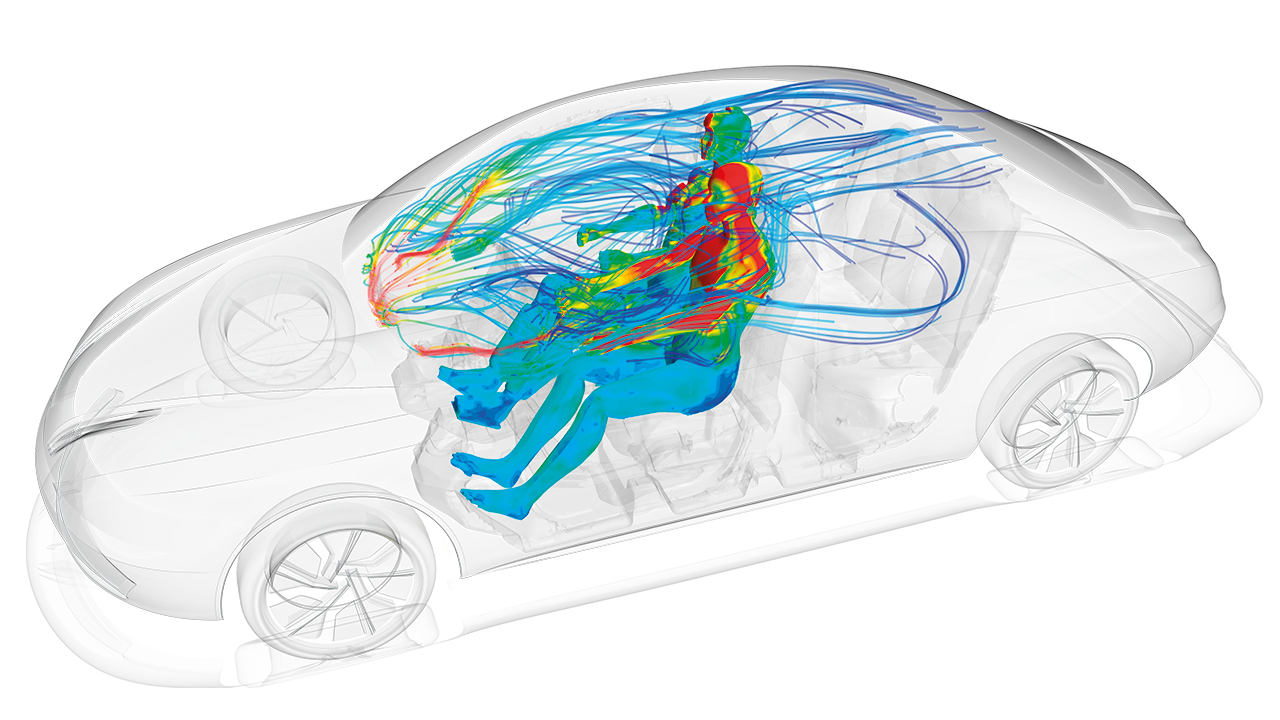

为了满足客户需求,早在新模型的设计阶段和对现存车型的进一步开发阶段,欧拓使用了一系列广泛的自主研发模拟软件。这些软件将汽车制造商的单独需求和欧拓的深度专业技术结合起来。

借助这款软件,欧拓对汽车的车辆振动噪声特性(噪声、振动、舒适性) 进行预测和优化,从而为汽车的减噪做出决定性的贡献。例如,欧拓开发了GOLD模拟软件,用于对汽车阻尼材料进行基于需求的开发。这一软件不仅优化了阻尼材料的体积、重量和质量,还显示了这些零件在汽车中的最佳安装位置。这使得阻尼材料和车体面板能以最佳的方式进行组合。

高性能的REVAMP和VisualSISAB软件用于汽车内部地板零件隔音消噪性能的分析、优化和验证。这些零件包括地毯系统以及舱壁、车轮罩和地板的隔音垫。设计这一软件的目的是为了实现声学特性和产品重量间的完美平衡。这使得欧拓为进一步提升汽车内部声学设计和减轻汽车重量做出了重要贡献。

欧拓开发的模拟软件还用于引擎舱零件隔热性能的计算和进一步增强,以及对材料疲劳度的测试和分析。

如需进一步信息,请联系 simulation@autoneum.com.

测量系统

欧拓测量系统 操作便捷的顶级技术

近50年以来,欧拓一直都是汽车声学专业测量系统的领先供应商。而且,欧拓从未停止研发创新系统与设备,用以对零件和材料的车辆振动噪声性能(噪声、振动、舒适性)进行测量。欧拓的测量系统在评估和比对减噪件和系统的功效上已到达立竿见影的境界。在为汽车制造商甄选声学组合方案的同时,也能保证客户能够得到最适合自身需求的产品。欧拓高度专业化的测量系统已经成为了全球认可的行业标准,在汽车制造商和供应商中都得以完满地运作。

如需进一步信息,请联系 ms-sales@autoneum.com.

欧拓测量系统优势一览:

- 精确、可靠和及时的测量

- 促进开发和增强转为汽车设计的声学组合方案

- 根据客户需求量身打造的应用

- 软件界面友好,操作简单直观

- 全行业认可的技术标准,被汽车制造商和供应商广泛采用

AFR

Measuring the Airflow Resistance of Porous Materials

The AFR (Airflow Resistance Measurement) system was designed to measure the airflow resistance of porous materials in an easy way without compromising in terms of measurement quality. The measurement results of the AFR system comply with ISO standard 9053:1991.

The AFR system offers:

- An extremely robust, stable, durable and high-quality construction

- Easy and intuitive operation also for non-experts

- Measurement of thin materials (fabrics or non-wovens) thanks to a special sample holder

- Rapid and easy fixation of measurement samples

- Easy transportation

Technical specifications:

| Overall dimensions: | 0.6 x 0.6 x 1.24 m (L x W x H) |

| Sample diameter: | 100 mm |

| Airflow Source: | Vacuum pump or compressed air |

| Standards: | ISO standard 9053:1991, method A (direct airflow method) |

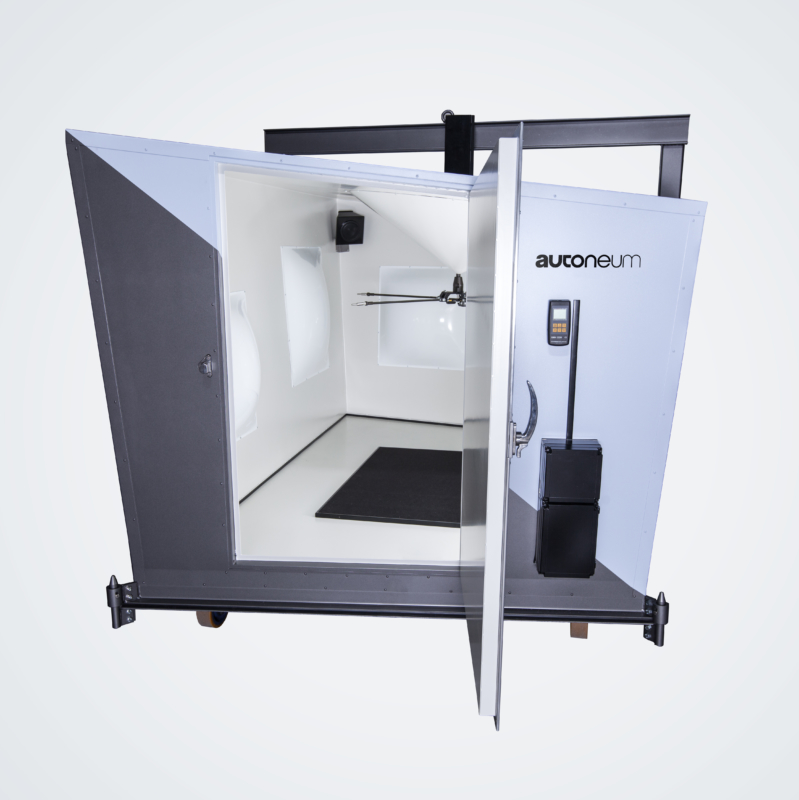

Alpha Cabin

A Global Standard for Acoustic Absorption Measurements

The Alpha Cabin has been especially designed for the measurement of acoustic absorption properties of materials and components used for the noise insulation of vehicles. The Alpha Cabin is significantly smaller than normal reverberation rooms and therefore ideally suited to use within limited space capacities. The acoustic absorption of the Alpha Cabin itself is also very low: Thanks to the high level of sound insulation, background noise in the frequency range of interest is kept to a minimum.

The Alpha Cabin offers:

- Development of enhanced sound packages and new materials and components for vehicles

- System recognized throughout the industry that is used by both vehicle manufacturers and suppliers

- Measurement results enable specifications for the absorption properties of NVH products (noise, vibration, harshness) to be drawn up

- Fast and easy measurement procedure thanks to user-friendly software

- Also ideal as a quality control system

- Easy transportation thanks to comparatively small size

- Can also be used in combination with Isokell to measure sound insulation

Technical specifications:

| Overall dimensions: | 3.22 x 2.37 x 2.03 m (L x W x H) |

| Volume: | 6.44 m³ |

| Sample surface area: | 1.2 m² |

| Frequency range: | 400 – 10’000 Hz |

| Standards: | Based on ISO 354:2003 |

Apamat II

Testing Acoustic Treatment: A Simple Test of Effectiveness

Apamat II was designed in order to compare and classify the complex range of soundproofing solutions currently used in the automotive industry. Apamat II tests the effectiveness of noise protection components and materials in terms of noise control, noise damping and noise insulation using just one system. Apamat II simulates

structure-borne and airborne excitation of the vehicle body-in-white under normal driving conditions. This realistic driving simulation enables valid and reliable measurement results to be obtained. Furthermore, the comprehensive suppression of secondary transmission paths in Apamat II facilitates a high dynamic range, making it particularly suitable for measurements of modern, high-performance noise control components.

Apamat II offers:

- Develop of new materials and concepts

- Measurement of acoustic efficiency by simulating material performance in the vehicle

- Measurement of noise control, noise damping and noise insulation using just a single system

- Combination of structure-borne and airborne excitation

- Quick and easy measurement

- Extremely robust, stable and durable system

Technical specifications:

| Overall dimensions: | 1,740 x 1,180 x 1,865 mm (L x W x H) |

| Frequency range: | 100 to 10,000 Hz |

| Accommodated sample size: | 840 x 840 mm |

ARTIS3

Assessment of structure-borne noise of acoustic packages

The innovative ARTIS3 system features an optimized experimental set-up for the performance assessment of structure-borne noise of acoustic packages. The dedicated software for testing, archiving and analysis makes it easy for the user to find the best solution in terms of performance, weight or cost.

ARTIS3 offers:

Robust evaluation of the acoustic effectiveness of a passive treatment versus structure-borne noise

Immediate and easy measurement process

Easy to transport thanks to comparatively small size

Technical specifications:

| System dimensions: | 920 x 920 x 1’490 mm (L x W x H) |

| Frequency range: | 100 to 800 Hz |

| Sample size: | 643 x 544 mm |

| Output: | Structure-borne insertion loss |

ATLAS

Measures acoustic insulation on small samples

ATLAS – short for “Airborne Transmission Loss Analysis System” – measures the acoustic insulation and transmission loss of interior components such as carpets, inner dashes and floor insulators. The system enables measurements of small samples with a diameter of no more than ten centimeters compared to the previous testing standard of around one square meter in size. This allows faster, cheaper and more environmentally-friendly transmission loss tests already in project pre-development.

ATLAS offers:

Overcomes limitations of current methods, where results may strongly depend on the sample edge conditions

Measures Transmission Loss (TL) of single layers and multilayers on small samples (100mm Diameter)

Rapid, easy and reliable data evaluation

Technical specifications:

| System dimensions: | 850 x 1210 x 1’240 mm (L x W x H) |

| Frequency range: | 100 to 3000 Hz |

| Sample size: | 100 mm diameter |

| Output: | Normal incidence transmission loss |

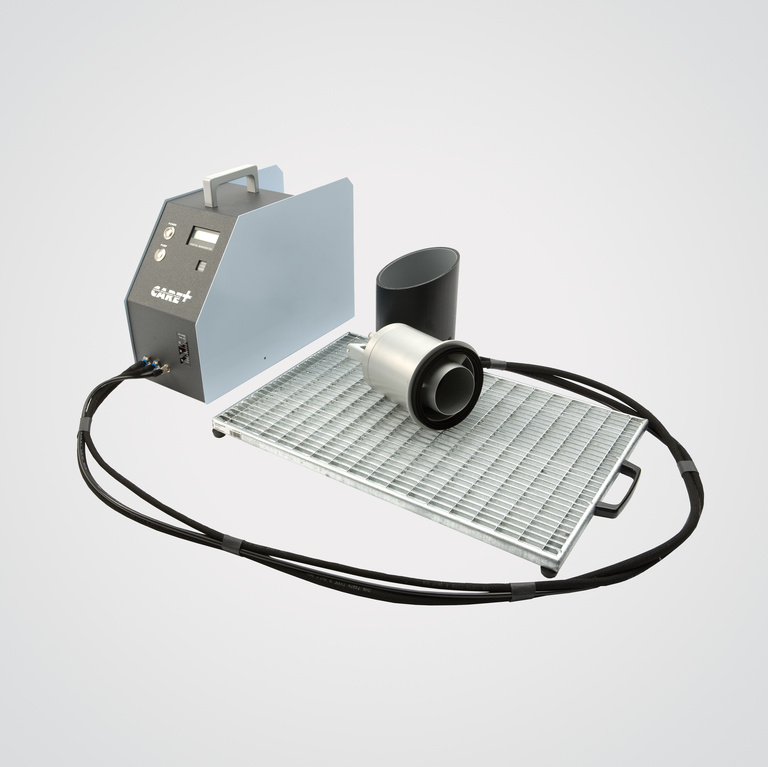

CARE+

Easy and Non-Destructive Airflow Resistance Measurements of Materials and Parts

The control of airflow resistance in the production of materials and components is a growing requirement in the automotive industry. CARE+ (Concentric Airflow Resistance Evaluator) is an apparatus designed to measure the airflow resistance of materials and parts. Measuring non-destructively, CARE+ is particularly applicable in the quality control of parts and materials.

CARE+ offers:

- Non-destructive air flow resistance measurements

- Ideal system for quality control

- Measurements of single or multi-layer materials or parts

- Easy transportation

Technical specifications:

| Overall dimensions: | 440 x 180 x 305 mm (L x W x H) |

| Bell overall dimensions: | 145 mm |

| Recommended range of airflow resistances: | 200 to 4’000 Ns/m3 |

| Recommended sample thickness: | less than 20 mm |

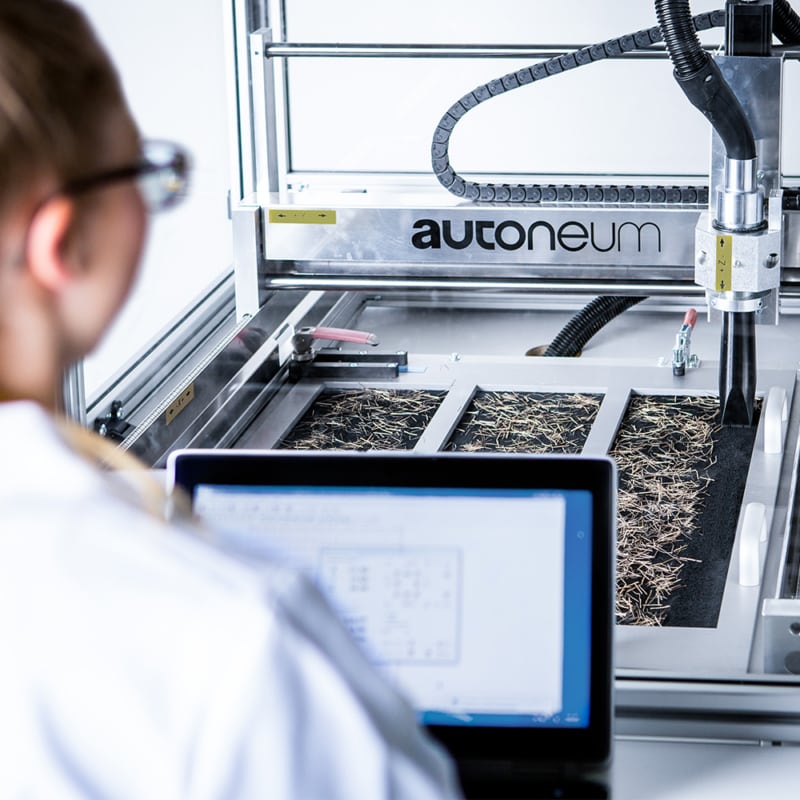

Carpet Cleanability Analyzer

Objective assessment of the Carpet Cleanability

The “Carpet Cleanability Analyzer” measurement system has been developed to analyze and compare the cleanability of different carpet surfaces. Per measuring cycle, three carpet samples soiled with strongly adhering particles, such as grains of sand or wool fibers, are cleaned by a robot-guided suction arm with controlled pressure. The measurement system calculates the cleanability and dirt resistance of the respective carpet technology based on the residue on the carpet surface and the weight difference of the samples.

Carpet Cleanability Analyzer offers:

- Robust, automated measuring method that works with all carpet surfaces (tufting and non-woven carpets)

- Only one operator necessary for the measuring process

- Repeatability of the results thanks to the robot-guided measuring process and the methodology used

- Representativeness – the methodology in use is similar to the way used by the car owners to clean their vehicle carpet.

- Quantitative assessment of the carpet cleanability

Technical specifications:

| System dimensions: | 150 x 95 x 180 cm (L x W x H) |

| Number of samples: | 3 |

| Dimensions of standard sample: | 180x620mm |

| Suction head speed: | 7m/min |

ELWIS

The Leading Measurement System for the Analysis of Porous Materials

ELWIS (Evaluation of Light Weight Impedance System) offers a full and rapid characterization of porous materials based on the analysis of a single sample. The ELWIS system consists of the ELWIS-A and ELWIS-S components which can be used independently from each other although both applications are needed for a complete material simulation.

ELWIS-A measures acoustic parameters that are needed to evaluate the acoustic performance of sound insulation and sound-absorbing multi-layer materials. An additional impedance tube for absorption measurements at higher frequencies is available for ELWIS-A.

ELWIS-S measures structural parameters that are needed to simulate the dynamic and acoustic behavior of sound packages in the medium to low frequency range (including the “Poisson Ratio” for foam materials).

ELWIS is very easy to operate: Thanks to its user-friendly software, the system can also be used to obtain reliable results by users with only limited experience in the characterization of porous materials.

ELWIS offers:

- Measurement system for obtaining material parameters for the simulation of components (e.g. using SISAB or SEA software)

- Swift comparison of performance of alternative systems or materials

- Rapid, easy and reliable data evaluation on the basis of a single material sample

- Supersedes large databases with material parameters for the compilation of sound packages

- Can also be used as a quality control system

- Adaptable to a wide range of materials and parts

- Combination of the benefits of inverse methods with innovative data evaluation and the latest material knowledge

- Easy-to-operate software also for non-experts

Technical specifications:

| Overall dimensions: | 0.85 x 2.21 x 1.24 m (L x W x H) |

| Accommodated sample size: | ELWIS-A: 60 mm diameter ELWIS-A additional option: 29 mm diameter ELWIS-S: 100 mm diameter |

| Frequency range: | ELWIS-A: 200 – 3,400 Hz ELWIS-A additional option: 1000 – 6,300 Hz |

| Standards: | Fulfills ASTM (E-1050) and ISO (10534-1/2) For impedance tube measurements (measurements between 200 and 3,400 Hz or up to 6,300 Hz with the additional option) |

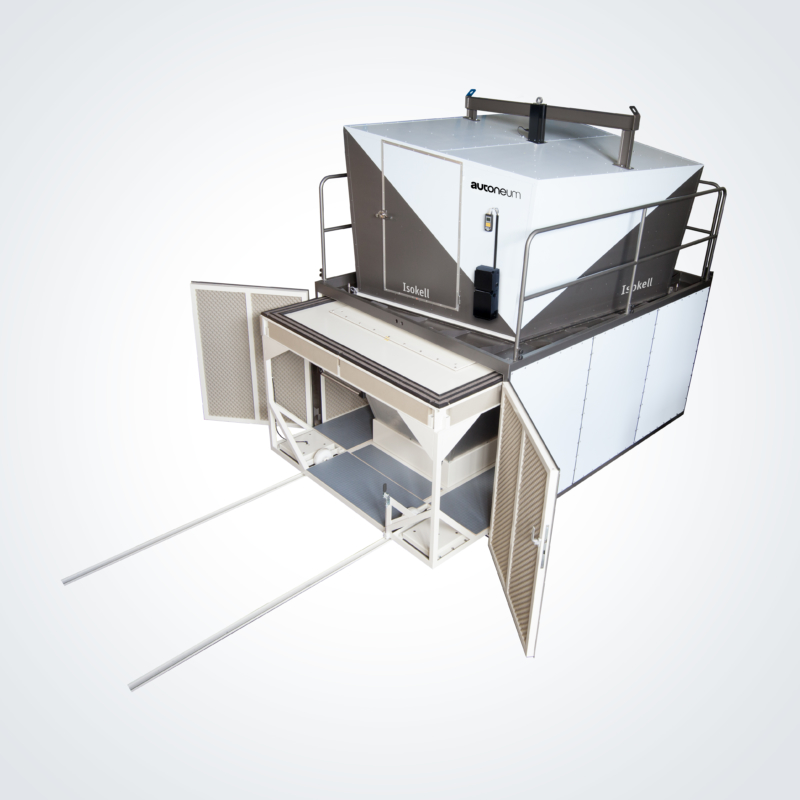

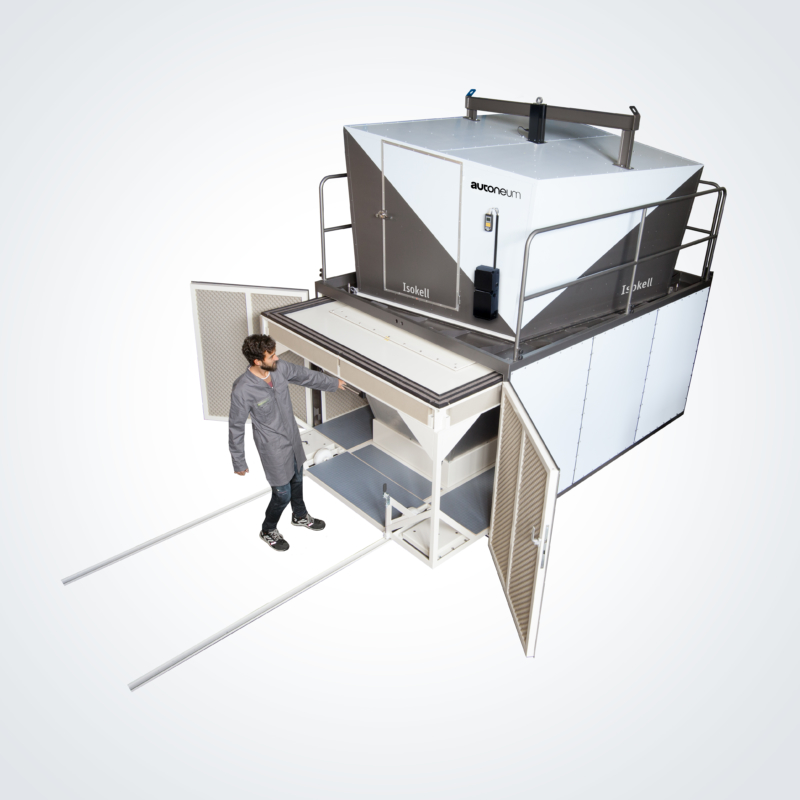

Isokell

Precise Measurement of Airborne Noise Insulation

Isokell offers a flexible method geared specifically to the needs of the automotive industry for measuring airborne noise insulation and the transmission loss of vehicle components. The system is easier to use and less costly than traditional acoustic measurement systems.

Isokell offers:

- Time savings thanks to horizontal sample mounting

- Measurement of flat samples or components

- Fast and easy measurement procedure thanks to user-friendly software

- Easy transportation thanks to reduced size

Used in combination with Alpha Cabin, it can also measure absorption

Technical specifications:

| Overall dimensions: | 3.4 x 2.5 x 3.75 m (L x W x H) |

| Sample apertures: | 1.0 x 1.2 m (standard flat samples) 1.5 x 2.0 m (larger parts) |

| Frequency range: | 125 – 6’300 Hz |

Porpos

User-friendly Measurement of Porosity of Felts and Foams

The Porpos system measures the porosity (ratio of air to overall volume) of felts and foams on the basis of the so-called “air-based” method. Via a process of alternately compressing and decompressing air, the porosity of the sample under analysis can be derived from the resulting pressure changes. Owing to the user-friendliness of the measurement procedure, Porpos is suitable not only for experts as the measurement system guides the user through the entire procedure while the system software controls the measurement cycle and automatically evaluates the results.

Porpos offers:

- Fast and easy measurement procedure thanks to user-friendly software

- Automatic evaluation of the measurement results by the software

- Suitable for a wide range of porous materials such as felts and foams

- Measurements of up to 100% sample porosity possible (pure air)

- High measurement quality

Technical specifications:

| Sample holder dimensions: | 50 mm long cylinder with 40 mm diameter |