Exterior components for light vehicles

Engine bay

The engine bay is the vehicle area where most of the noise and heat sources are concentrated. With innovative lightweight and multifunctional components, Autoneum helps automobile manufacturers to address new regulations for pass-by noise and CO2 emissions.

Autoneum offers the following products among others for application in the engine bay:

*Components specifically for vehicles with combustion drive

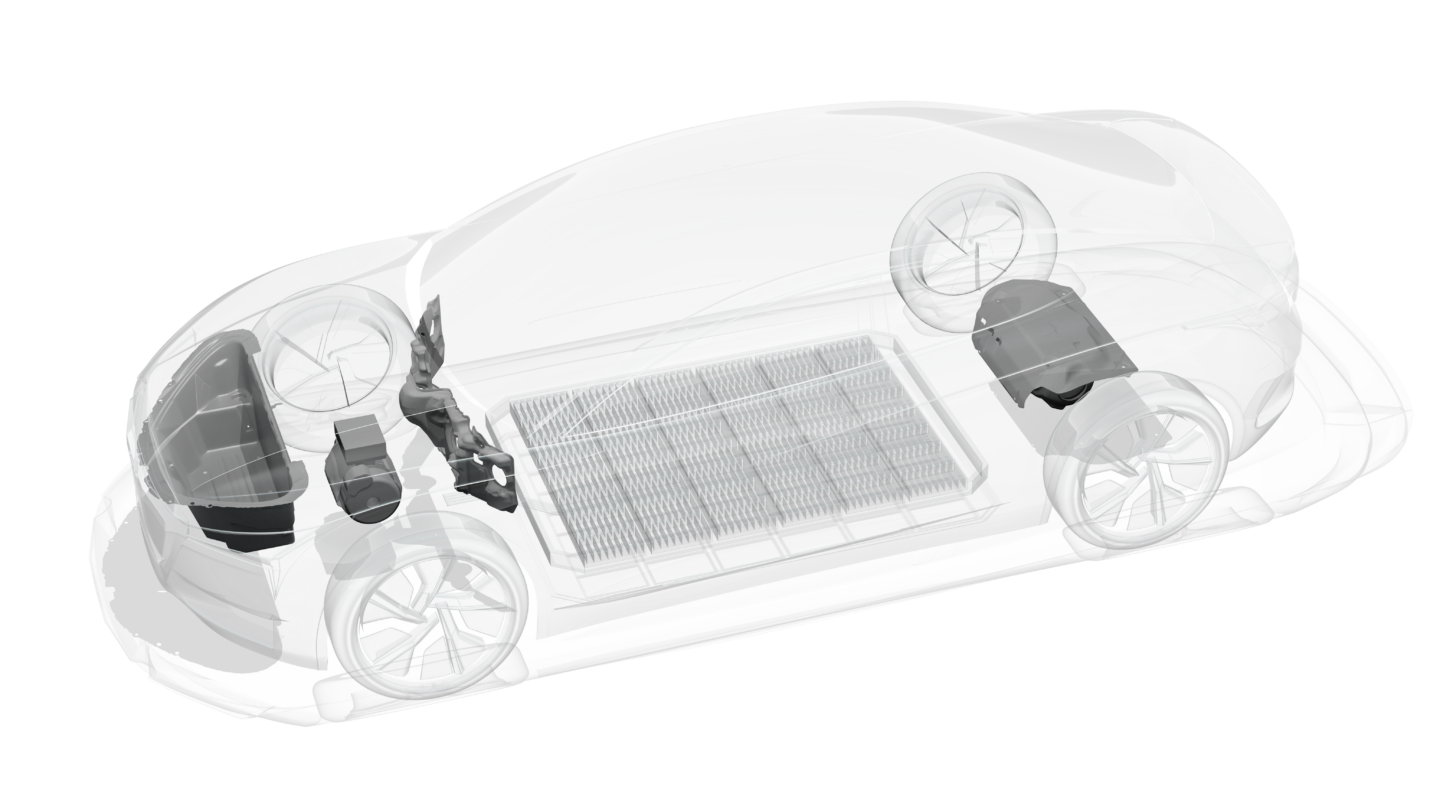

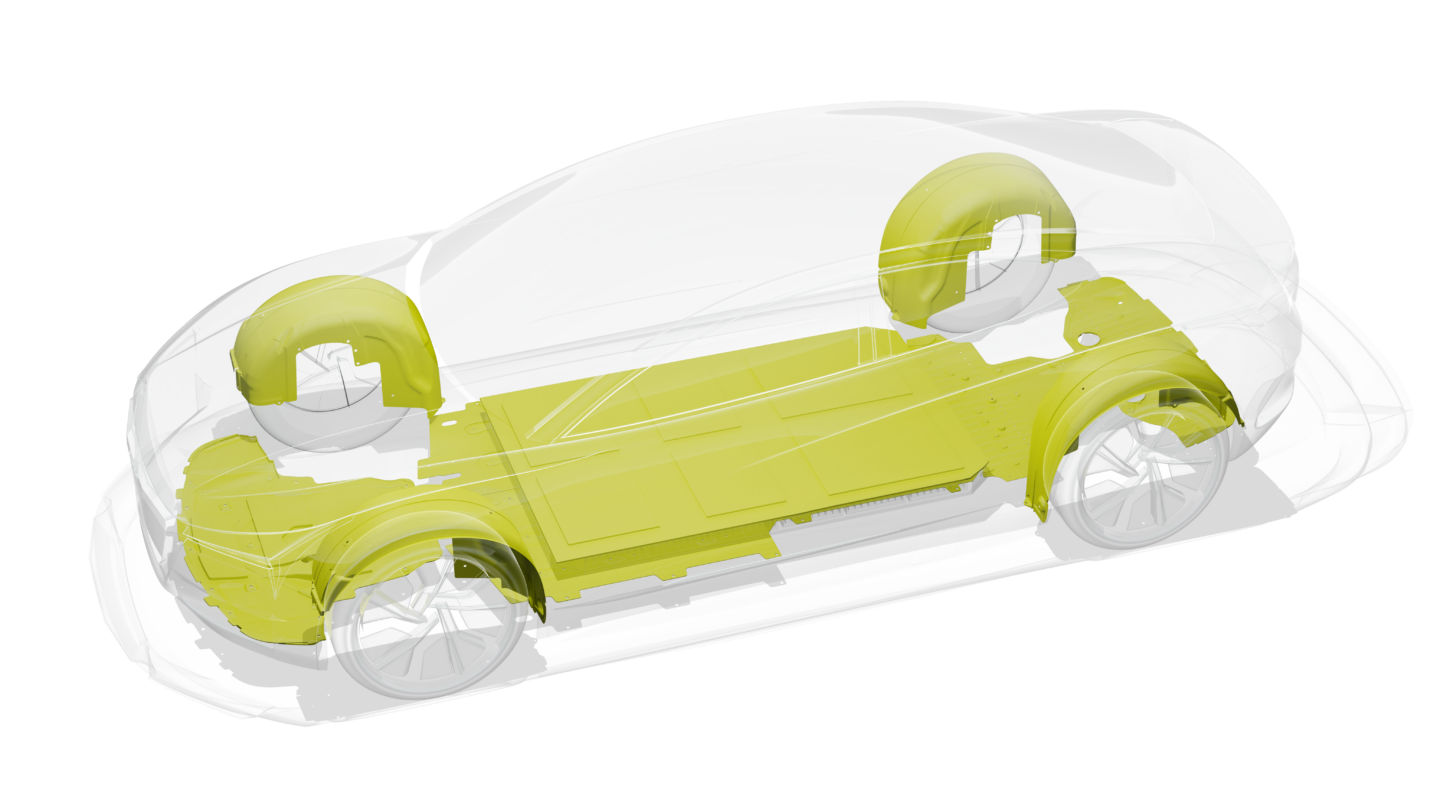

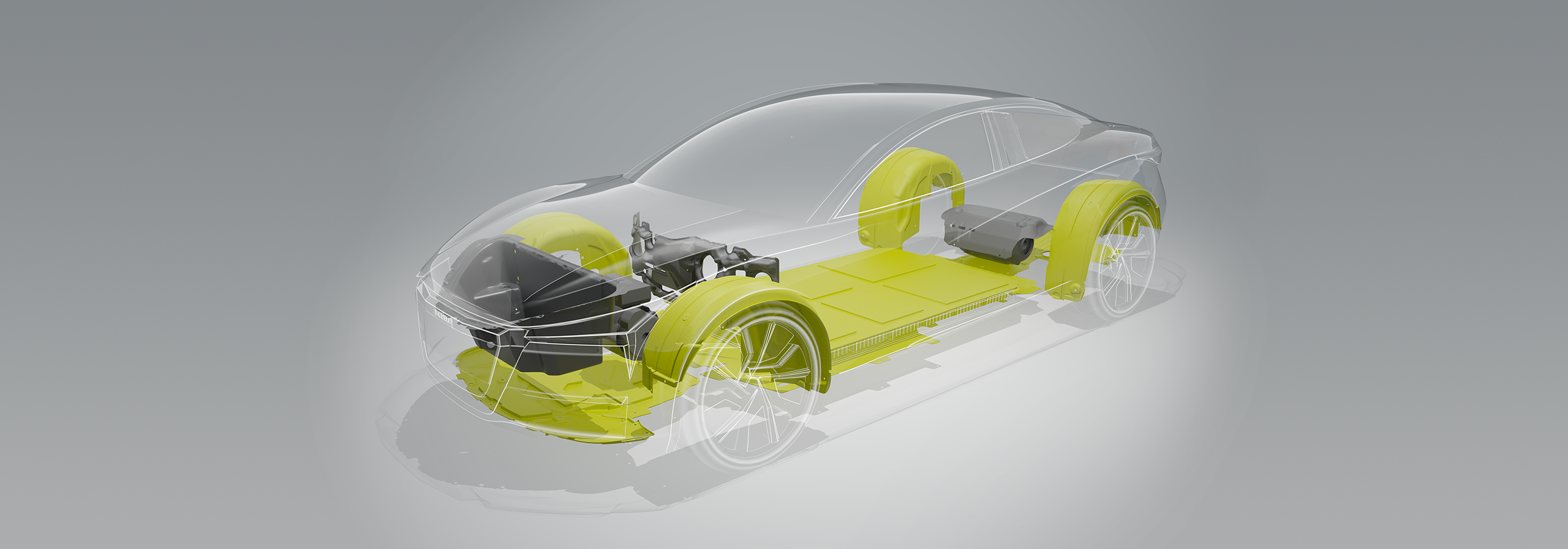

Underbody

Textile-based and correspondingly lightweight underbody systems of Autoneum absorb noise and therefore simultaneously reduce the interior and exterior noise of cars. They also enhance the aerodynamics of a vehicle. This leads to lower fuel consumption and reduced vehicle emissions.

Autoneum offers the following products among others for underbody application:

*Components specifically for vehicles with combustion drive

Technologies for the vehicle exterior

Technologies for the engine bay

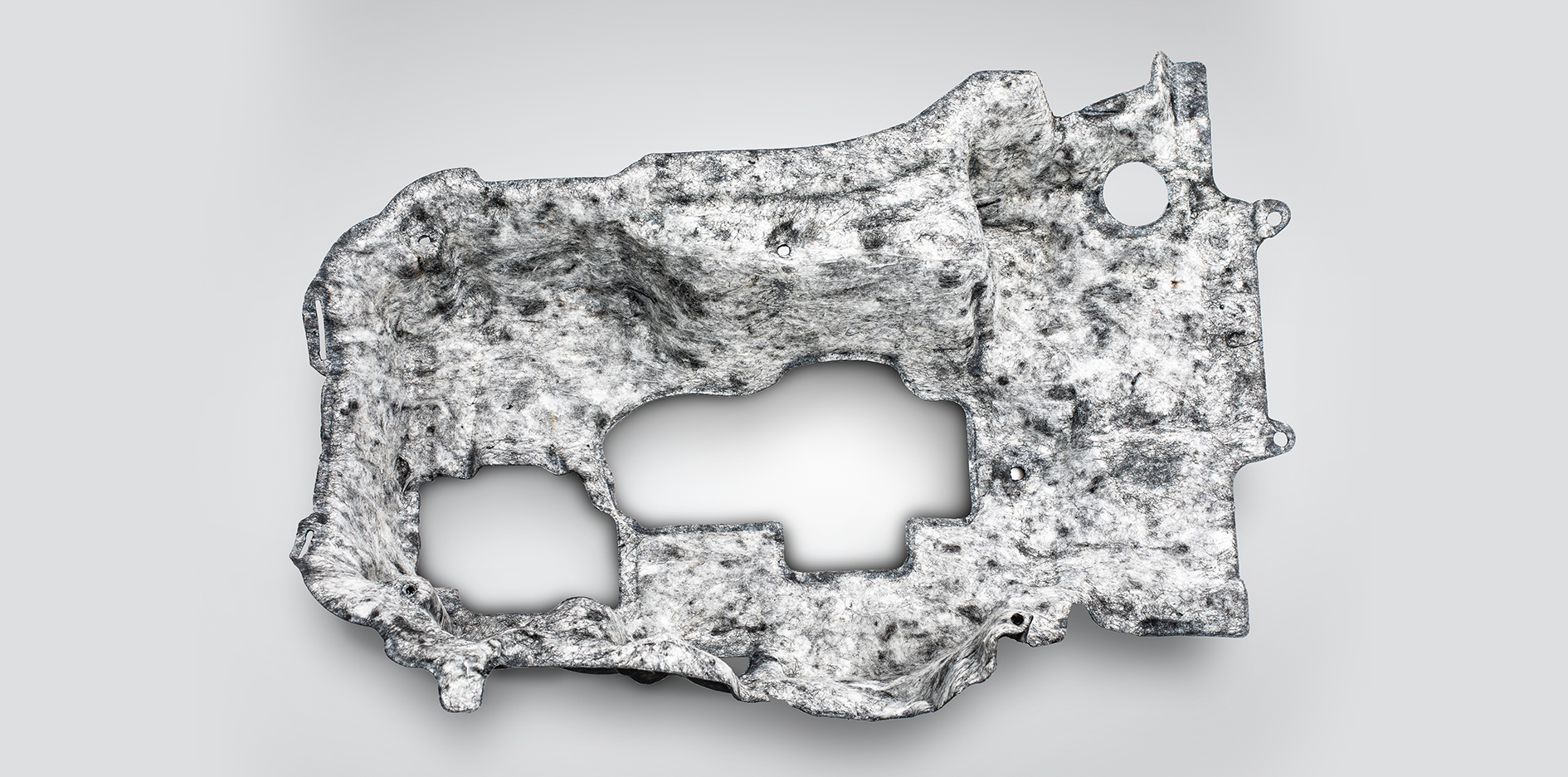

Hybrid-Acoustics PET

Sustainable noise protection in the engine bay

With Hybrid-Acoustics PET, Autoneum has adapted its textile interior technology Hybrid-Acoustics for use in the engine compartment. The patented innovation is based on a unique fiber material that acts as an insulator and absorber at the same time. Among others, Hybrid-Acoustics PET is used to encapsulate electric motors, thereby reducing noise directly at the source and particularly attenuating high-frequency sounds of the electric drive unit. This key technology accordingly ensures optimum noise protection in the passenger cabin and greater driving comfort.

At the same time, components made of Hybrid-Acoustics PET convince with their low weight. Compared to conventional insulators, they are up to 40 percent lighter and thereby contributing to a greater driving range. They are also flameproof and find application as powertrain-mounted insulators for combustion engines thanks to their temperature resistance of up to 180°C.

The parts, which consist to a large extent of recycled PET fibers, are produced waste-free and are completely recyclable – an outstanding life cycle assessment compared to equivalent components in the engine bay.

Theta-FiberCell

Key Technology for Engine Encapsulations

Innovative engine encapsulations enhance the efficiency and sustainability of vehicles: The heat storage in the engine bay achieved with the encapsulations reduces fuel consumption at the next cold start, which in turn leads to lower vehicle emissions.

Autoneum recognized the growing importance and far-reaching potential of the thermo-acoustic insulation of vehicles at an early stage and has developed an innovative material: Theta-FiberCell combines the benefits of the fiber absorber Theta-Fiber and foam absorber Theta-Cell. Theta-FiberCell, the key technology for engine encapsulations launched on the market in 2012 is based on Autoneum’s long-standing experience and takes into account customer-specific product requirements such as optimum noise protection and integrated thermal insulation. The high temperature stability entailed by this thermal insulation is also of major importance for vehicle manufacturers: Theta-FiberCell is barely flammable and can withstand temperatures of up to 200°C.

Theta-FiberCell also appeals due to its lightweight and displays high resistance towards engine vibrations. Theta-FiberCell can be used for engine encapsulations mounted onto the engine or vehicle.

As well as the acoustic absorption of interior (by up to four decibel) and exterior (by up to eight decibel) noise, the fiber-foam solution enables heat to be stored for long periods after the vehicle has been parked. After being switched off for 12 hours, the temperature of an engine with Theta-FiberCell encapsulation is six degrees higher than one without this special insulation.

This difference in temperature results in a higher engine oil temperature and less internal friction of the engine which in turn enhances the efficiency and sustainability of vehicles. Each six degrees increase in engine oil temperature reduces CO2 emissions by three grams per kilometer driven.

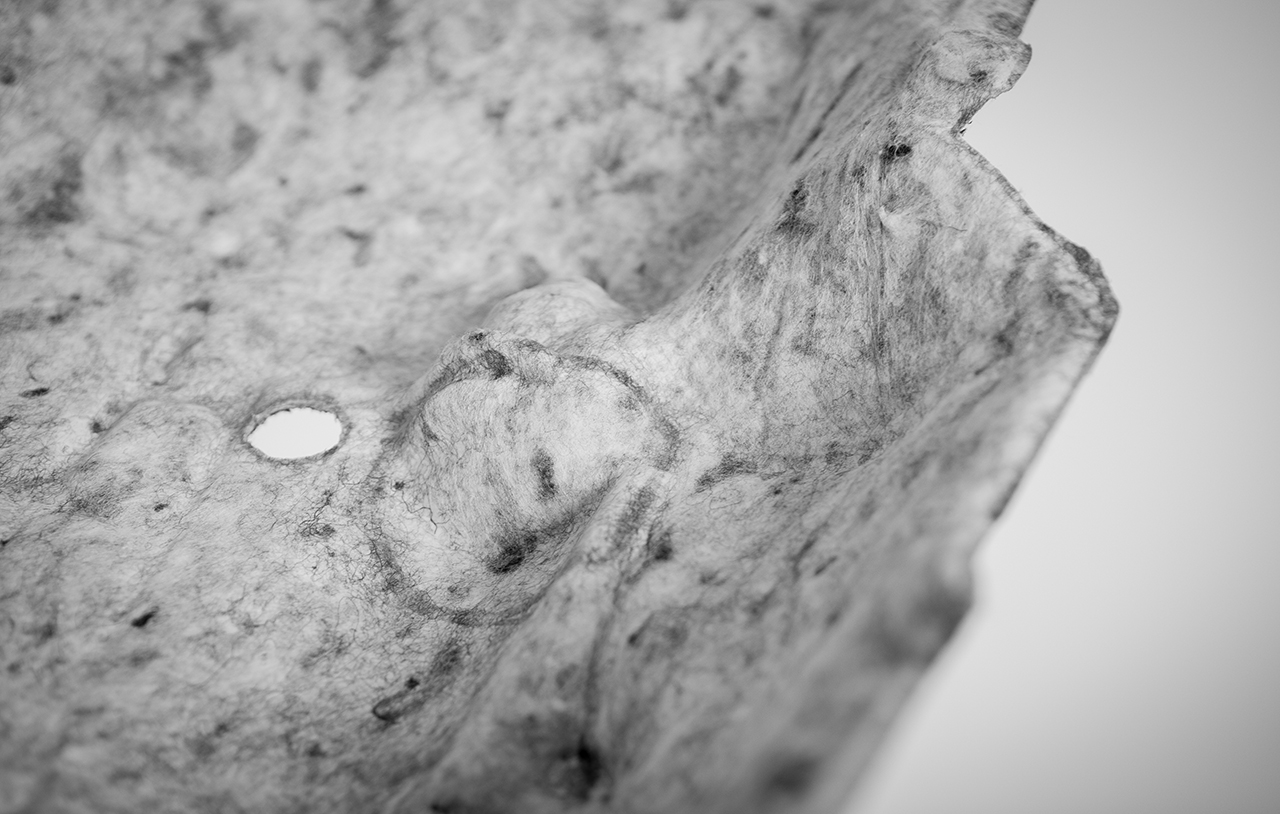

Theta-Fiber

Multifunctional Non-Woven Technology

With Theta-Fiber, Autoneum offers a robust and multifunctional non-woven material for treatment in the engine bay. Up to 70 percent recycled fiber material is used for manufacturing components based on the semi-structural Theta-Fiber material technology.

Theta-Fiber stands out against conventional non-woven components above all thanks to its high temperature resistance: While traditional thermoplastic materials are able to withstand temperatures of up to 150°C, noise and thermal insulation parts based on Theta-Fiber can also be applied at temperatures of up to 200°C.

Compared to traditional heavy engine covers made of solid plastic, Theta-Fiber engine covers achieve weight savings of up to 60 percent, reduce the interior and exterior noise of vehicles and insulate heat generated by the engine.

Due to its high temperature stability, resistance to vibrations, lightweight, good acoustic properties and integrated thermal insulation, Theta-Fiber is a core element of Autoneum’s innovative engine encapsulations.

Theta-Cell

Durable and Lightweight Foam Components

Theta-Cell is an innovative polyurethane foam material developed by Autoneum. It is used for different applications such as lightweight and multifunctional hoodliners, outer dashes, tunnel insulators and battery covers. Compared with conventional acoustic absorbers, Theta-Cell components can be used to achieve weight reductions of up to 60 percent as well as high thermal insulation.

Products based on Theta-Cell are able to withstand temperatures of up to 180°C at peak; they meet customer requirements and legal provisions with regard to the non-flammability of components for the engine bay. They are also oil and water-repellent and help to reduce the interior and exterior noise of vehicles.

Theta-Cell combines with the felt material Theta-Fiber to form the substrate Theta-FiberCell that is used for the engine encapsulations provided by Autoneum.

Technologies for the underbody

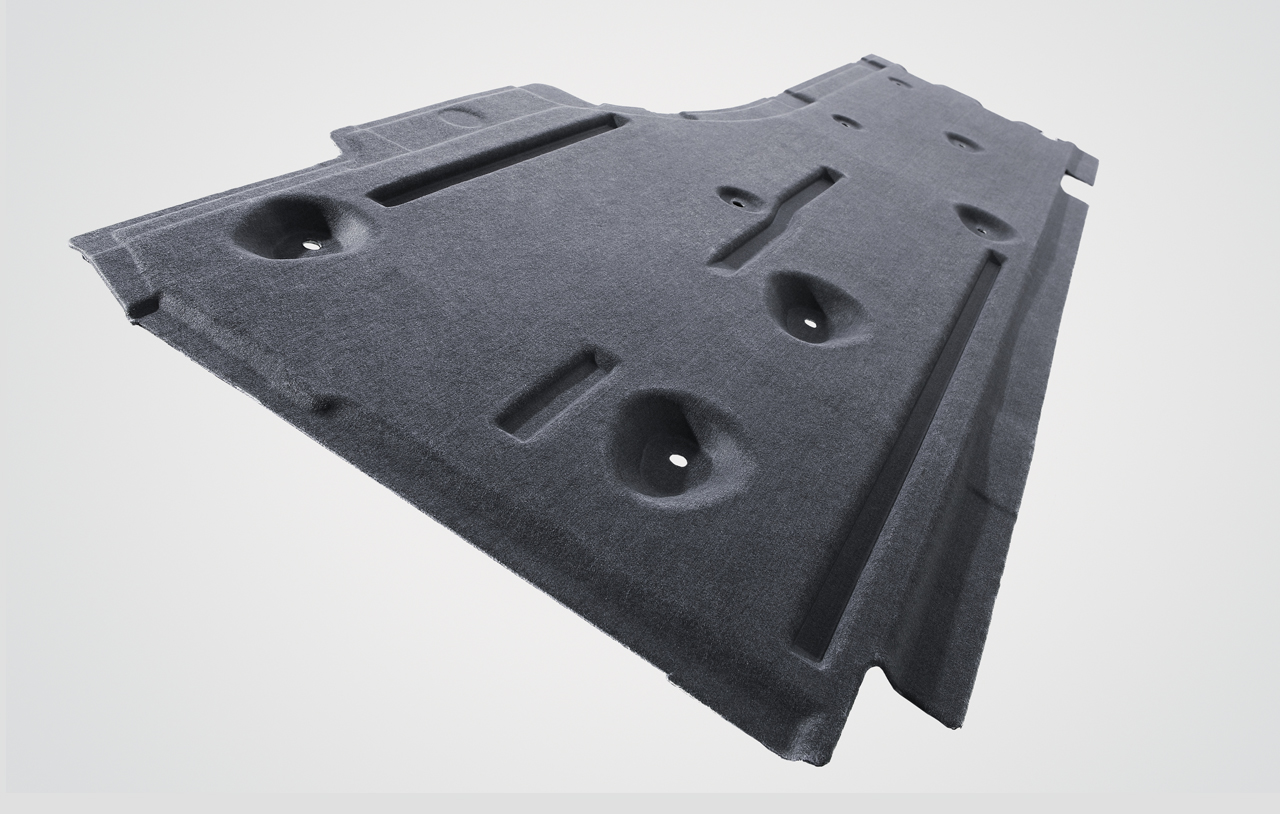

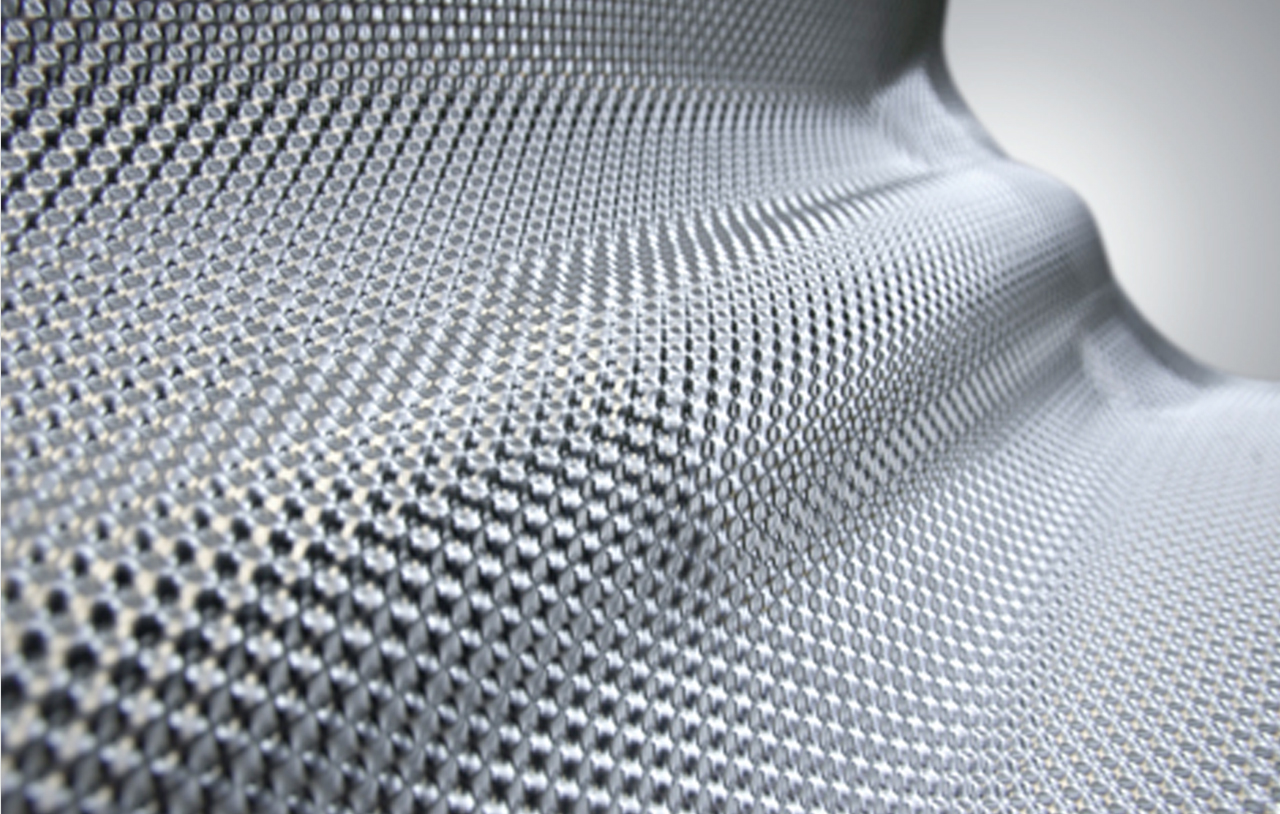

Ultra-Silent

Light, Durable and Acoustic

With underbody systems made of Ultra-Silent, Autoneum offers the most lightweight textile underfloor systems for vehicles: They are up to 50 percent lighter compared with equivalent components made of plastic.

Underbody systems made of Ultra-Silent also convince with a high degree of impact resistance and optimum stone chip protection. The PET-based, glass-free mono-material is resistant against water and heat and fully recyclable. At the same time, Ultra-Silent absorbs sound and in doing so reduces the vehicle noise by up to two decibels.

In addition, underfloor systems made of Ultra-Silent enhance the aerodynamics of vehicles by reducing their air resistance. This contributes to lower fuel consumption and thereby reduces CO2 emissions.

Propylat

50% lighter than plastic components

Autoneum’s sustainable, textile and lightweight Propylat technology reduces both interior and exterior noise of vehicles. The versatile technology consists of a mixture of synthetic and natural fibers with high recycled content. Thanks to the flexible material composition and the variable density and thickness of the porous material, its acoustic and other technical properties can be tailored to individual customer requirements.

This allows for a versatile application of Propylat in a variety of interior and exterior components such as wheelhouse outer liners, trunk trim, underbody systems and carpets. For instance, Propylat-based wheelhouse outer liners significantly reduce rolling noise both inside and outside the vehicle while at the same time offering optimum protection against stone chipping and spray water.

In terms of sustainability, Propylat always contains a high proportion of recycled fibers – up to 100% in some variants – and can be manufactured with zero waste. Thanks to the full vertical integration of Propylat and Autoneum’s extensive expertise in recycling processes, the technology also contributes to significant waste reduction.

Propylat PET, which consists of 100% PET, of which up to 70% are recycled fibers, is fully recyclable at the end of product life and is part of Autoneum Pure, the Company’s sustainability label for technologies with excellent environmental performance throughout the product life cycle.

Alpha-Liner

Optimum tire noise reduction

Alpha-Liner is a multifunctional wheelhouse outer liner that reduces tire noise with high efficiency and thus makes the vehicle quieter and lighter. Alpha-Liner is based on Autoneum’s newly developed technology, with which noise absorption can be adapted to the specific requirements of the vehicle model for the first time. To achieve this effect, a thin coated surface is applied on the tire side. The porosity of the coating can then be controlled according to the necessary absorption properties, the bottom part of the wheelhouse outer liner requires stronger noise treatment, which maximizes acoustic absorption.

Wheelhouse outer liners made of Alpha-Liner offer additional advantages as well. They are easy to clean and robust thanks to the plasticized surface, making them more resistant to stone chipping and ice accumulation in the wheelhouse. Compared to corresponding components made of plastic, Alpha-Liner convinces with a lower weight, ensuring a greater driving range especially for electric vehicles.

In addition, the components are produced in a sustainable manner. Production scrap of the wheelhouse outer liners, which are primarily made of recycled PET fibers, can be fully recovered and recycled.

RIMIC

Heat Protection and Noise Absorption

Heatshields are used in vehicles primarily to provide protection against the heat that arises in the engine bay and the exhaust system. In order to shelter this radiant warmth, these shields are heat-resistant up to 500°C.

Heatshields based on Autoneum’s lightweight, fully recyclable RIMIC technology not only protect against heat. At the same time, they also lower noise emissions of vehicles. This noise reduction is achieved by means of a special perforation developed by Autoneum. It converts the airborne sound into thermal energy and absorbs it. Using in-house production processes, these perforations are applied specifically only at predefined areas to ensure optimal heat protection and durability.

The acoustic performance of heatshields is controlled by the number of openings per shield. RIMIC can be used as a single layer or in combination with the Theta-Cell acoustic absorption technology in order to facilitate the absorption of high-frequency sounds of between two and six kilohertz.